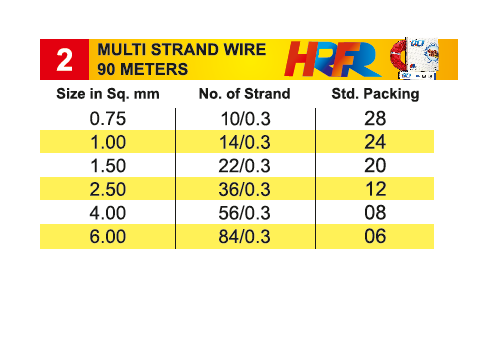

HRFR MULTISTAND WIRE

HRFR insulation in multi-strand wires — meaning Heat Resistant and Flame Retardant insulation — provides a combination of electrical safety, thermal stability, and enhanced protection against fire hazards. It is widely used in residential, commercial, and industrial wiring systems due to its superior performance under stress and high-temperature environments.

Key Benefits of HRFR Insulation

1. Enhanced Heat Resistance

HRFR insulation allows wires to operate continuously at higher temperatures (up to 85°C) compared to standard PVC wires, which are typically rated only up to 70°C. This capability reduces the risk of insulation softening or deformation in hot environments or under heavy electrical loads.

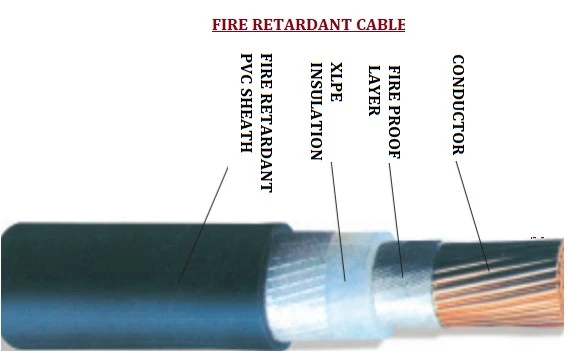

2. Flame Retardant Properties

The insulation composition prevents the rapid spread of fire, even under high heat conditions. The flame-retardant additives increase the oxygen and temperature index of the insulation, making it difficult for the wire to catch or propagate fire. This property is vital for reducing fire damage in homes, commercial buildings, and industrial complexes.

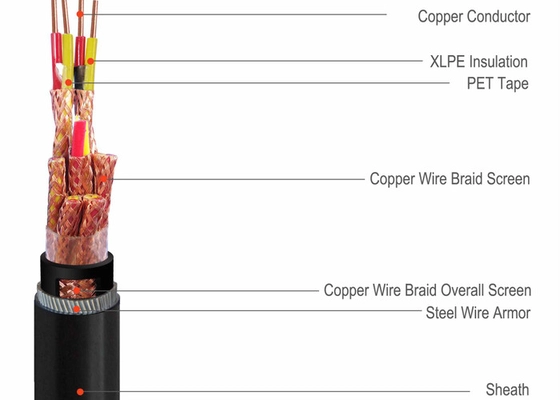

3. Improved Electrical Safety

Because of its higher insulation performance and reduced current leakage, HRFR insulation ensures increased electrical reliability and safety. Some variants (such as HRFR with advanced S3 technology) also repel termites and rodents, preventing insulation damage and the risk of short circuits.

4. Extended Durability and Load Handling

HRFR wires can endure higher current loads without degrading insulation quality, thereby extending cable life and preventing premature failure. This also improves performance under fluctuating power conditions common in industrial and commercial facilities.

5. Eco-Safety and Compliance

Modern HRFR insulation materials are engineered to meet strict environmental and electrical safety standards, limiting the emission of toxic gases during electrical faults or overheating events.

Applications

-

Household wiring for fans, lighting, and concealed electrical systems

-

Industrial machinery and automation control panels

-

Commercial complexes and data centers with high electrical loads

-

Transport and infrastructure projects requiring resistance to heat and vibration.

HRFR (Heat Resistant Flame Retardant) insulated multi-strand cables are widely used in industries and sectors that require safety, flexibility, and heat resistance in electrical wiring. These cables prevent flame propagation, withstand high temperatures, and provide superior insulation reliability.

Key Industries Using HRFR-Insulated Multi-Strand Cables

1. Building and Construction

Used in residential, commercial, and public buildings for wiring fans, lights, air conditioners, and power outlets. The HRFR property ensures minimal smoke and heat spread in case of a fire.

2. Industrial Manufacturing

Industries such as steel, cement, textiles, and chemicals depend on HRFR cables for operating heavy machinery and control panels, where heat and electrical stress are common.

3. Automotive and Transport

These cables are implemented in automobiles, railways, shipbuilding, and aircraft systems, where vibration, movement, and temperature variations require flexible and flameproof wiring.

4. Power and Energy

Used in power plants, substations, and renewable energy systems (like solar farms) where high current transmission and fire safety are critical.

5. Telecommunication and Electronics

In data centers and telecommunication facilities, HRFR cables are valued for their low smoke emission and reliability under load, ensuring minimal downtime and safe network operation.

6. Infrastructure and Public Utilities

Deployed in airports, hospitals, educational institutions, and metro projects where fire safety regulations demand use of HRFR or halogen-free wiring systems.

In summary, HRFR-insulated multi-strand cables are integral to construction, industrial automation, transportation, power distribution, telecommunications, and public infrastructure — all sectors that require high thermal endurance and superior fire protection